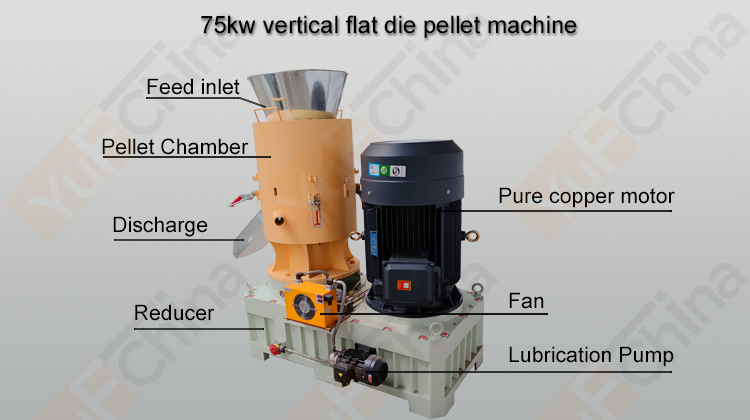

75kw vertical flat die pellet machine

Raw materials for Flat Die Pellet Machine

The flat die pellet machine (or pellet mill) processes a wide range of biomass materials to produce high-density pellets for fuel, industrial use, or animal bedding. Key raw materials include:

Wood residues: Logs, branches, sawdust, wood shavings, and wood offcuts.

Agricultural waste: Rice husk, rice straw, wheat straw, corn stover, sorghum stalks, soybean stalks, cotton stalks, sunflower straw, peanut stalks, grape pomace, and miscanthus.

Energy crops: Bamboo debris, sugarcane bagasse, and EFB (empty fruit bunches) from palm oil extraction.

Herbaceous biomass: Grasses, shrubs, and crop residue such as alfalfa and miscanthus.

These materials are densified into uniform pellets throughring die pellet millsorflat die pelletizers, enabling efficientbiomass granulation. The resulting pellets serve as sustainable alternatives for heating, power generation, and industrial energy needs.

Advantage of Flat Die Pellet Mill

Specially good at processing low-adhesive and hard-molding materials. Widely used in biomass pellet production and other pellet forming industries.

Equipped with automatic main shaft lubrication system for sustained operation.

Some Tips for the Pelleting Machine

Flat Die Sawdust Pellet Machine for efficient wood pellet extrusion.

The YuFChina biomass coarse fiber pellet mill is specially designed for high-fiber materials.

The main flat die pelleting machine adopts high-grade driving reducer, wear-resistant bearings, and high-alloy die plates to ensure efficient, stable driving, low noise, and long lifespan. The new type flat die sawdust pelletizer features a quick-release anchor mechanism and inverter-controlled variable feeding for uniform material distribution.

Customizable Compression Ratio.

With rich experience, we optimize die compression ratios for specific materials. The flat die pellet press transforms raw materials into biomass pellets in one step.

Extended Running Hours for Flat Die Wood Pellet Machines.

Continuous operation enabled by automatic lubrication systems. Daily maintenance ensures long-term stable performance.

Complete Production Line for a Small Pellet Plant

The wood complete set production line includes crusher, hammer mill, dryer, flat die pellet mill, cooler, and packing machine.

First, biomass raw materials are crushed into powder by the crusher or hammer mill. The crushed materials are dried to 15-20% moisture for optimal flat die granulation. Materials are transferred to the flat die biomass pelletizer via a screw elevator and silo/bunker bin. Finished particles are cooled and screened by the cooling machine, then packed and sealed via belt conveyor.

In this process, equipment can be replaced or deleted based on specific needs, such as adjusting the flat die configuration or densification parameters.

Whole Process Show

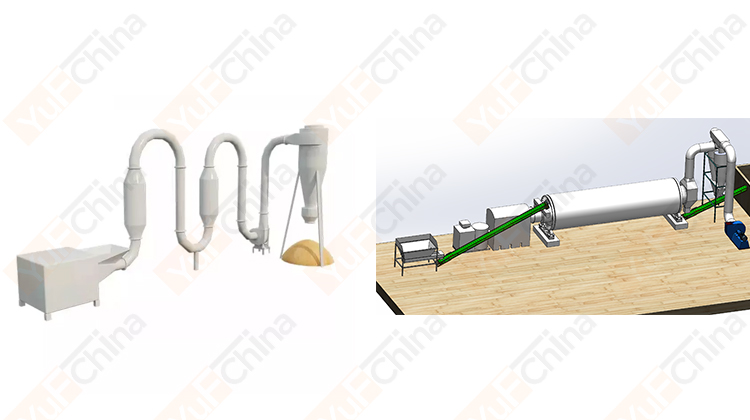

1. Crushing system

Multi-Function Hammer Mill is needed if raw materials as wood with diameter вүӨ20cm. Being Feed into the crushing chamer by #1 Inlet, then the crushed powder will be set out from the mesh screen by the force of centrifugal pressure and fan suction.

2. Dryer system

The humidity of sawdust will be controlled by a Airflow Dryer or a Rotary Drum Dryer.

Both the rotary drier and air-flow dryer are drying the wet materials by hot air. Hot-air Furnace / Heat Exchange Chamber will be installed to provide heating air for the whole drying section, Fuels are optional by wood, biomass pellet, gas, fuel oil, etc.

In different cased we have the specific choice for the drying machine.

Sometimes after dryingwe collect dried materials with moisture between 8% and 20%.

3. Pellet system

By auger feed, the Wooden Pellets Machine is composed of a bunker, pressing roller, flat die, reducer and motor, which is used to produce dense fuel particles from biomass raw materials through the extrusion of the press roll and the flat die.

Die Specification plays important role for the production, on the basis of qualified type and humidility of raw materials, we should take more attention for the Die Compress Ratio.

4. Cooling and Screening system

Simple Structure Pellet cooller & screen machine is designed speciall for the small scale pellet plant factory.

Considering the cost, YuFChina also design a new type of Chain Coolling Conveyor to finish the 3 in 1 Functions, which are used for pellet coolling, screening and transporting. With long Long life, simple maintenance,simple operation and so on.

We will recommed the suitable ones according to your budget, site conditions and production capacity.

5.Packing system

This packaging machine uses weighing, sealing, and conveying methods, and is suitable for quantitative packaging of granular materials in industries such as feed, grain, fertilizer, rice, seeds, chemicals, and food.

Advantages: Automatic control, adjustable feeding speed, high precision, and easy operation.

Specification

| Model | 560 |

|---|---|

| Power | 75kw |

| Output for wood or fiber | 800-1000 kg/h |

| Die Size | 4-12mm |

| Machine Size | 1600*950*1750mm |

| Machine Weight | 2500kg |

Flat Die Biomass Pellet Machine Technical Data

| Model | Power (kw) | Capacity for wood (kg/hr) |

|---|---|---|

| 200 | 7.5 | 80-100 |

| 260 | 15 | 100-200 |

| 300 | 22 | 200-300 |

| 350 | 30 | 300-400 |

| 400 | 37 | 400-500 |

| 450 | 45 | 500-600 |

| 450 | 55 | 600-800 |

| 560 | 75 | 800-1000 |

GET IN TOUCH WITH US