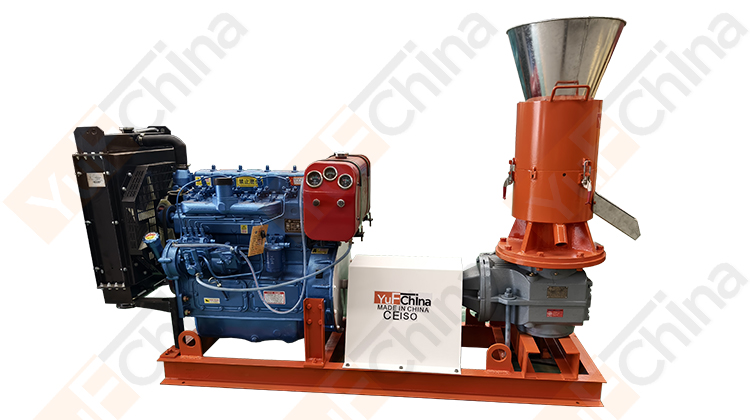

Diesel engine flat die pellet machine

Diesel - Powered Biomass Flat Die Pellet Machine Introduction

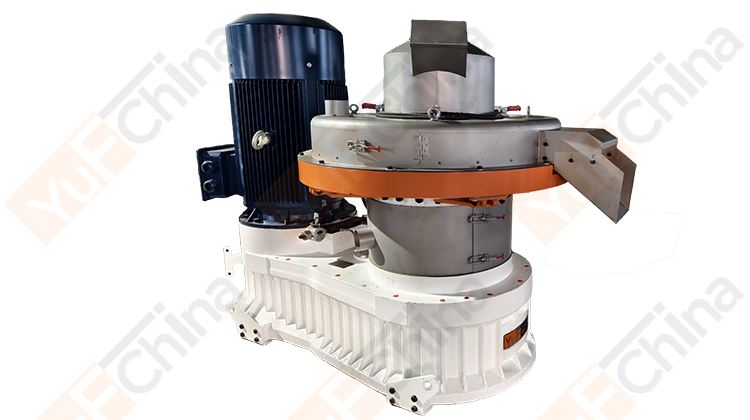

The Diesel - Powered Biomass Flat Die Pellet Machine, a cutting - edge, self - contained unit in the realm of biomass processing equipment, is engineered to transform a plethora of biomass feedstocks—ranging from crop straws, wood shavings, sawdust to bagasse and animal manure—into high - density, cylindrical biomass pellets. Distinguished by its diesel - engine - driven mechanism, this flat die pelletizer offers unparalleled operational flexibility, especially in off - grid, rural, or power - unreliable environments where traditional electric - powered pellet mills fall short.

Working Principle

At the core of this diesel - propelled pellet making machine lies a high - torque diesel engine, which acts as the prime mover, driving the entire pelletizing assembly. Biomass materials enter the machine via the feed hopper and are conveyed to the flat die chamber—a critical component equipped with precision - drilled holes. Here, diesel - actuated pressure rollers, with their robust construction and optimized surface profiles, exert intense compressive force on the biomass against the flat die plate. This high - pressure compression forces the biomass through the die holes, creating continuous cylindrical extrusions. Subsequently, adjustable pellet cutters, calibrated for precision, slice these extrusions into uniform pellets, ensuring strict adherence to pellet size specifications, density requirements, and shape consistency—key parameters in the quality control of biomass pellets. The diesel engine's stable and consistent power output mitigates fluctuations, guaranteeing smooth operation even when processing tough, fibrous, or high - moisture - content biomass.

Key Advantages

1.Off - Grid Mobility and Portability: This diesel - driven flat die pellet press features a rugged, trailer - mounted design, enabling seamless transportation across diverse terrains. Its independent power source liberates it from reliance on external electrical grids, making it an ideal on - site biomass processing solution for remote farms, forestry plantations, and disaster - stricken areas, significantly slashing the costs associated with material transportation.

2.Robust Diesel Engine Performance: Integrated with a heavy - duty, turbo - charged diesel engine, the machine delivers superior torque and sustained power, ensuring reliable operation under heavy - load conditions. It can adeptly handle a wide spectrum of biomass materials, accommodating variations in moisture levels (optimally between 12 - 18%), hardness, and fibrousness with minimal performance degradation.

3.Feedstock Versatility: Similar to its electric counterparts, this diesel - powered flat die pellet machine exhibits remarkable adaptability, capable of efficiently processing an extensive array of biomass raw materials. Its modular design allows for easy adjustment of operational parameters, ensuring consistent pellet production quality regardless of the feedstock's unique characteristics.

4.Rapid Start - up and Responsiveness: Diesel engines offer near - instant ignition, enabling the machine to commence operation within minutes. This quick - start functionality proves invaluable for intermittent production schedules, emergency biomass conversion needs, or scenarios requiring rapid equipment deployment.

5.Minimal Maintenance and Durability: Boasting a simplified mechanical architecture and the inherent durability of diesel engines, this pellet machine demands infrequent upkeep. Regular lubrication, filter replacements, and basic engine tune - ups are typically sufficient to maintain peak performance over extended operational lifespans.

Applications

The diesel - powered biomass flat die pelletizer finds extensive utility across multiple sectors. In rural communities and remote agricultural regions, it empowers local farmers and small - scale entrepreneurs to convert crop residues and farm waste into marketable biomass fuel pellets or nutrient - rich animal feed pellets on - site. In forestry operations, it efficiently processes wood residues, sawmill by - products, and logging waste into high - quality pellets for heating, power generation, or industrial applications. During natural disasters, power outages, or in military field operations, its self - sufficient nature provides a reliable and immediate solution for emergency biomass processing, ensuring uninterrupted production and energy supply.

In conclusion, the Diesel - Powered Biomass Flat Die Pellet Machine represents a revolutionary leap in biomass processing technology, seamlessly blending the mobility of diesel - driven systems with the efficiency of flat die pelletizing. Its multifaceted capabilities, reliability, and sustainability make it an indispensable asset for industries aiming to optimize biomass utilization and achieve energy independence.

GET IN TOUCH WITH US