75kw 65x75 wood pulverizer machine

High efficiency hammer mill is a kind of equipment specially used for crushing materials. It has the characteristics of simple structure, strong versatility, high productivity and safety usage. Following with some application areas and advantages for the high efficiency hammer mill.

Application of Wood Grinder

Produce Biomass Pellet -The high efficiency hammer mill can crush various types of wood, straw, bamboo and other biomass raw materials into pellets for the production of biomass fuel, biomass power generation, etc.

Produce Feed Pellet -The hammer mill can crush various feed raw materials into fine particles, which improves the nutritional value and palatability of the feed and is beneficial to the digestion and absorption of animals.

Food processing -High-efficiency grinders can grind food raw materials into particles of different sizes for the production of various food additives, condiments, etc. Chemical industry: High efficient grinders can grind various chemical raw materials into fine particles to improve chemical reaction efficiency and product quality.

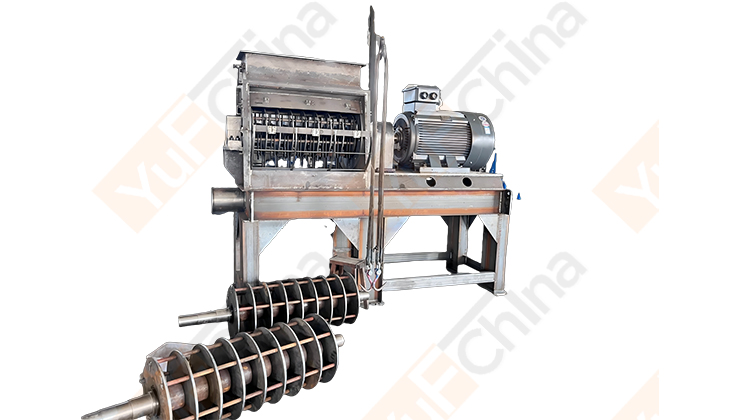

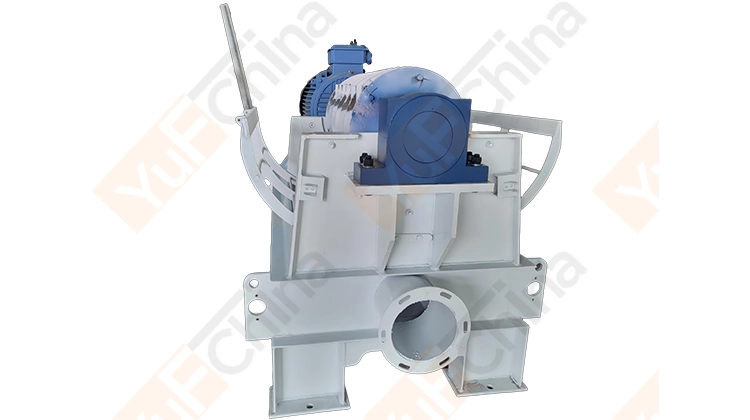

Working Principle of Sawdust Making Machine

The high efficiency crusher adopt high-speed rotating hammers and airflow impact to crush materials. During the operation of the equipment, first cut the materials into small pieces by the high-speed rotating hammers, and then the materials being impacted and collided by the high-speed air flow for further refine the material. Finally, after sieving, crushed products of different particle sizes are obtained.

Advantages of Sawdust Pulverizer

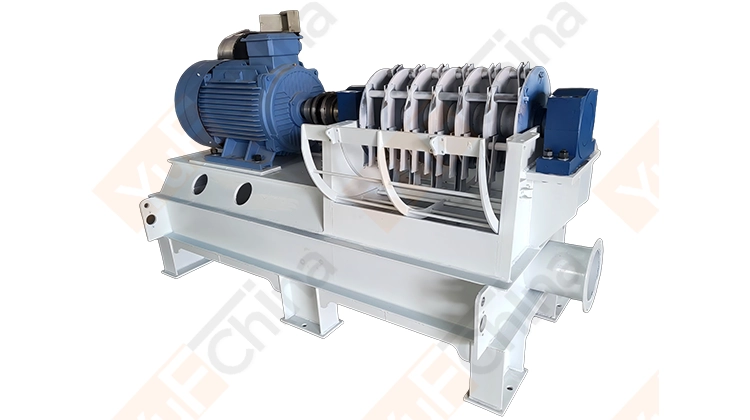

The vertical feeding design allows materials to fall directly into the crushing chamber, which is more suitable for processing heavier materials and granular materials. For example, food crops such as corn, sorghum, wheat, and beans, as well as granular materials such as small wood blocks and wood chips can be easily processed.

The design with feed guide allows material to fall into the crusher from two directions. So when the blades seriously worn out, we do not need to disassemble the rotor for replacement, but only needs to change the rotation direction of the motor for continuous production. This design greatly reduces maintenance time and improves work efficiency.

The screen mesh of the hammer mill is fully enclosed, and the materials can be discharged from all directions, which greatly improves production efficiency.

The quick-open screen pressing mechanism makes it easier to replace the screen and the pressing is more reliable.

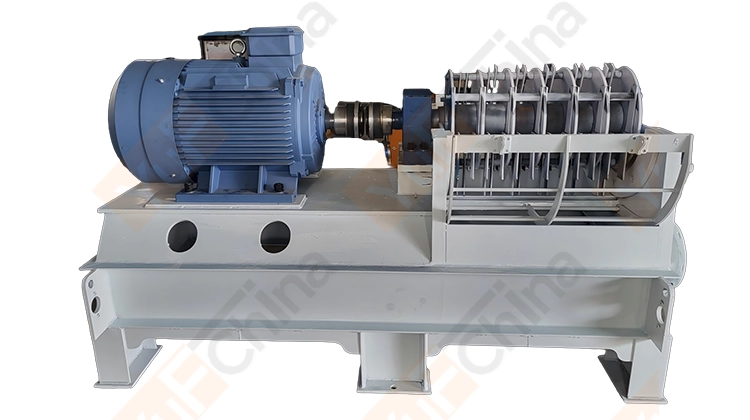

The rotor being treated by multiple precision experiments and tests such as dynamic balance, static balance and vibration to ensure that it runs more smoothly, has lower noise and has better performance.

The design equipped with cyclone separator and bag dust collection system makes cleaning and separation during the crushing process more convenient.

Technical Data

| 65X75 hammer mill Technical Data | |

|---|---|

| Name | 65X75 hammer mill |

| Capacity | 2-2.5 t/h |

| Power(kw) | 75KW |

| Hammers qty | 72pieces |

| Mesh | 2 pcs |

| Weight | 2.2T |

| Dimension | 2.1x1.7x1.5m |

Complete set -Hammer mill, Fan 11kw /15 kw, ПҶ800/ПҶ1000 cyclone, air locker, bag filter, wind pipes.

Hammer Mill Technical Data

| Model | Power(Kw) | Capacity(T) |

|---|---|---|

| 65x55 | 55 | 1-2 |

| 65x75 | 75 | 2-2.5 |

| 65x100 | 90 | 2.5-3 |

| 65x100 | 110 | 3-3.5 |

| 65x120 | 132 | 4-5 |

| 1300x1000 | 160/185 | 6-8 |

| 1600x1000 | 220 | 8-10 |

GET IN TOUCH WITH US