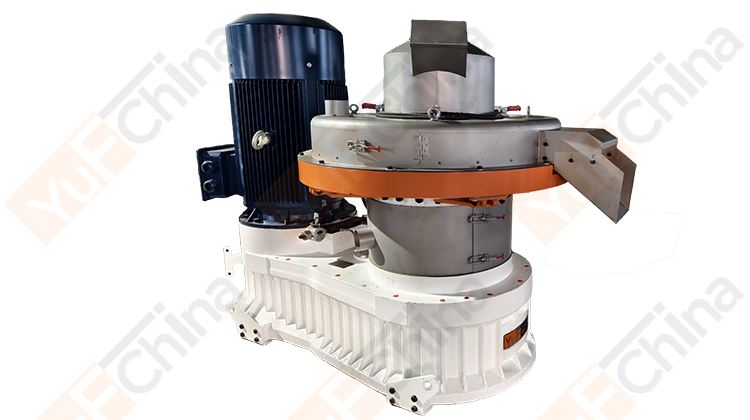

Commercial Forestry Chipper вҖ“1800 160kW Engine for Heavy Use

Features of Large Disc Chipper

Drive mode: Electric motor or diesel engine

Two feeding types: Top-feeding or side-feeding (via a speed-adjustable belt conveyor for log feeding)

The durable feeding conveyor effectively handles large wood materials

Widely applied in the production of paper, edible fungi, shaving boards, sawdust, high-density fiberboards (HDF), and fiberboards

Structure of Disc Chipper

The wood chipper is mainly composed of a base, chassis, feed port, cutting blades, adjustment mechanism, and electronic control system. The cutting blades and gap settings can be adjusted as needed to produce wood chips of different specifications and thicknesses.

Wood Disc Chipper Applications

* Used in paper mills

* Used in furniture factories

* Used in power plants and boiler plants

* Used for producing biomass pellets

Technical Parameter

| Model | 1800 |

|---|---|

| Rotation speed (rpm) | 420 |

| Blade QTY (piece) | 6 |

| Chip size (mm) | 20-35 |

| Input size (mm) | 500x500 |

| capacity (t/h) | 30-40 |

| Main power (kw) | 160 |

| Feed + discharge motor (kw) | 5.5+5.5 |

| Disc diameter (mm) | 1800 |

| Weight (t) | 8.5 |

| Feed conveyor length (mm) | 6000 |

| Discharge conveyor length (mm) | 10000 |

Disc Chipper Machine Models

| Model | Blade qty | Capacity (t/h) | Main power (kw) |

|---|---|---|---|

| 1150 | 6 | 10-12 | 55 |

| 1300 | 6 | 13-18 | 75 |

| 1600 | 6 | 15-25 | 110 |

| 1800 | 6 | 30-40 | 160 |

GET IN TOUCH WITH US