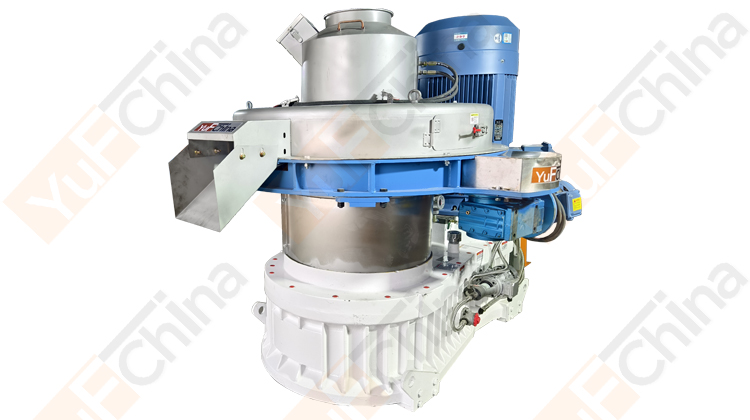

8th Generation Pellet Mill вҖ“ 4-Bearing Design with Down Push Device

Compared with traditional pellet machines equipped with upper push device, the 8th Generation Ring Die Biomass Pellet Mill adopts a down push system. This upgrade enables continuous discharging and significantly improves the high pellet forming rate characteristic of modern wood pellet machines. Notably, the redesigned structure facilitates efficient maintenance of critical components such as the ring die, rollers, and other wear-resistant parts, thereby extending the service life of the pellet mill while enhancing overall productivity.

Core Advantages

The 8th-generation biomass pellet mill is meticulously engineered to comprehensively boost production efficiency and user experience.

Overall Upgrades

Priority-optimizedDown Push Structure

The down push structure significantly improves material forming rate and ensures smooth, rapid discharge. Combined with the quick-release ring die and roller structure, maintenance becomes more convenient and efficient.

Reinforced Thickened Bearing Chamber

The thickened and strengthened bearing chamber effectively prevents fracture and abnormal wear, enhances equipment durability remarkably, and cuts down your long-term maintenance costs substantially.

Precision Four-bearing Layout

Upgraded from three bearings to four-bearing support, the four-point positioning ensures higher concentricity for smoother, quieter operation. The optimized maintenance structure also saves time and effort.

One-piece Cast Main Shaft

Replacing split welding, the one-piece cast thickened main shaft doubles structural strength and torque resistance, extending the equipment's service life.

Automatic Lubrication System

Longevity GuaranteeFull-automatic Lubrication System

The standard automatic lubrication pump delivers precise, timed lubrication to rollers and feed discs. It completely resolves the pain points of untimely and uneven manual lubrication, freeing up labor resources.

Forced Circulation Lubrication

Equipped with a high-flow circulation oil pump, it forces gear oil to circulate inside the reducer, dissipating frictional heat. Combined with the air-cooled system, it forms an efficient heat dissipation closed loop.

High-power Air-cooled Heat Dissipation

The external high-power air-cooled device works with the oil circulation system to force cooling of high-temperature oil, ensuring the temperature of returned oil stays within the safe range and preventing oil deterioration.

Upgraded Electrical Control System

Downtime ReductionDual Control: Touch Screen + Physical Buttons

Standard with dual systems of touch screen and physical buttons, supporting mobile remote intelligent control for intuitive and easy operation. Physical buttons serve as emergency backup for safer operation.

Soft-start Protection

Adopting soft-start technology, it smoothly regulates starting current to avoid impacts on the power grid and mechanical structure. With multiple protections against overload and phase loss, it guarantees production safety.

First-tier Brand Components

Strictly selected national-level brand components from Delixi, Chint, etc. It ensures the electrical control system is durable with extremely low failure rates.

Intelligent Safety Protection

Preventive MaintenanceReal-time Oil Flow Monitoring

Equipped with an oil flow detector to monitor lubricating oil flow in real time. It triggers automatic alarms immediately upon detecting abnormalities, preventing wear caused by oil shortage.

Intelligent Variable-frequency Speed Regulation

The automatic frequency converter intelligently senses current load and adjusts feeding speed automatically. It reduces frequency and unloads under overcurrent conditions, effectively protecting the motor and reducer.

Full-cycle Overload Protection

Covers the entire process of startup, operation and shutdown. It responds to foreign object jamming or sudden load increase in milliseconds, cutting off power instantly to eliminate motor burnout risks.

8th Gen vs. 7th Gen

7th-generation

Top Push System

Average Capacityпјҡ1.5-2.2t/h

Maintenance Timeпјҡ4 hrs

Forming Rateпјҡ92-94%

8th-generation

Down Push System

Average Capacityпјҡ1.7-2.5t/h +30%

Maintenance Timeпјҡ2.5hrs -38%

Forming Rateпјҡ96-98% +4%

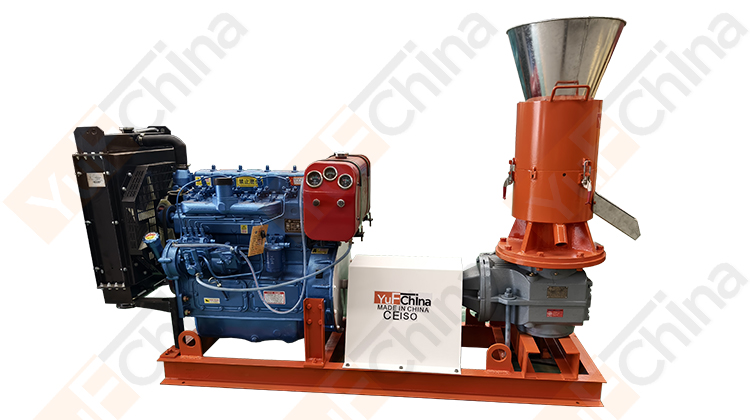

Biomass Pellet Raw Material Processing

Professional Solutions for Multi-category Raw Materials

Woody Materials

Wood logs, wood branches, wood chips, wood shavings, and other wood-based waste materials.

Agricultural Waste

Rice husk, sunflower husk, peanut shells, empty fruit bunches (EFB) from palm, alfalfa, bamboo, fruit shells, and crop stalks.

Other Materials

Cow dung, coconut shells, bamboo, activated carbon, sugarcane bagasse, cement, ash, fertilizers, chemicals, etc.

вҖў All raw materials must be dried before use to meet the required moisture content.

вҖў Remove metals, gravel and other impurities from woody raw materials to prevent equipment damage.

вҖў Agricultural raw materials should be crushed to an appropriate particle size, usually below 10mm.

вҖў Special raw materials (e.g., cow dung, sludge) require pre-treatment such as dehydration.

вҖў It is recommended to mix raw materials in proper proportions to achieve optimal pellet forming results.

8th Generation Ring Die Biomass Pellet Mill Technical Specifications

| Model | Power(kw) | Capacity(t/h) | Pellet Size(mm) | Dimension(mm) | Weight(t) |

|---|---|---|---|---|---|

| XGJ460 | 55 | 0.6-0.8 | 6-12 | 1700*1000*1580 | 3.8 |

| XGJ560A | 90 | 1.1-1.3 | 6-12 | 2240*1200*1650 | 4.8 |

| XGJ560B | 110 | 1.4-1.7 | 6-12 | 2240*1200*1650 | 5 |

| XGJ560C | 132 | 1.5-2.1 | 6-12 | 2480*1200*1800 | 5.3 |

| XGJ560D | 160 | 2-2.5 | 6-12 | 2480*1200*1800 | 5.3 |

| XGJ700A | 160 | 2-2.5 | 6-12 | 2680*1300*2100 | 8.6 |

| XGJ700B | 160 | 2.3-2.8 | 6-12 | 2680*1300*2100 | 8.6 |

| XGJ850A | 220 | 2.7-3.4 | 6-12 | 2630*1300*2200 | 13 |

| XGJ850B | 250 | 3.1-3.8 | 6-12 | 2630*1300*2200 | 13 |

| XGJ850C | 280 | 4-4.5 | 6-12 | 2630*1300*2200 | 13.2 |

7th Generation Wood Pellet Machine Technical Data

| Model | Power(kw) | Capacity(t/h) | Pellet Size(mm) | Dimension(mm) | Weight(t) |

|---|---|---|---|---|---|

| XGJ460 | 55 | 0.6-0.8 | 6-12 | 1700*1000*1580 | 3 |

| XGJ560 | 90/110/132 | 1.1-2.1 | 6-12 | 2240*1200*1650 | 4-5 |

| XGJ700 | 160 | 2-2.5 | 6-12 | 2680*1300*2100 | 8.5 |

GET IN TOUCH WITH US