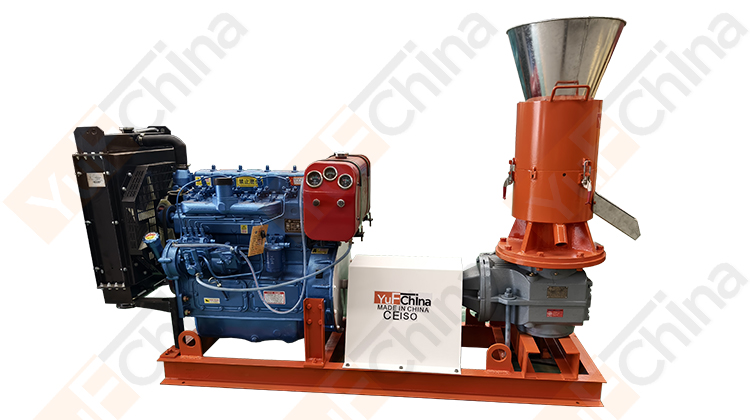

8th Gen Biomass Pellet Machine Complete Set Shipped: Core Components and Features

Components Included:

1. Pellet Machine Main Unit

- The core of the system, featuring a flat die and rollers for compressing biomass materials (e.g., sawdust, straw) into pellets. Supports customizable die hole sizes (2.5вҖ“10 mm) for diverse pellet diameters.

2. Feeding Auger

- Automatically transports raw materials (e.g., wood waste, agricultural residues) to the pelletizing chamber, ensuring consistent feedstock supply.

3. Automatic Lubrication Pump

- Enhances machine durability by reducing friction in critical parts like bearings and gearboxes, extending operational lifespan.

4. Cyclone Dust Collector

- Removes airborne particles during processing, improving workplace safety and pellet quality.

5. Touchscreen PLC Control Cabinet

- User-friendly interface for monitoring and adjusting parameters (e.g., motor power, pellet length). Integrates Siemens-brand motors and precision gearboxes for reliable performance.

Key Advantages:

- High Efficiency: Processes 200вҖ“800 kg/h depending on material and configuration.

- Versatility: Compatible with diverse biomass inputs (straw, rice husk, wood waste) and ideal for small to medium-scale production.

- Durability: Reinforced gearboxes, alloy steel rollers, and corrosion-resistant components ensure long-term operation.

For further technical details or customization options, refer to the product specifications in.

GET IN TOUCH WITH US