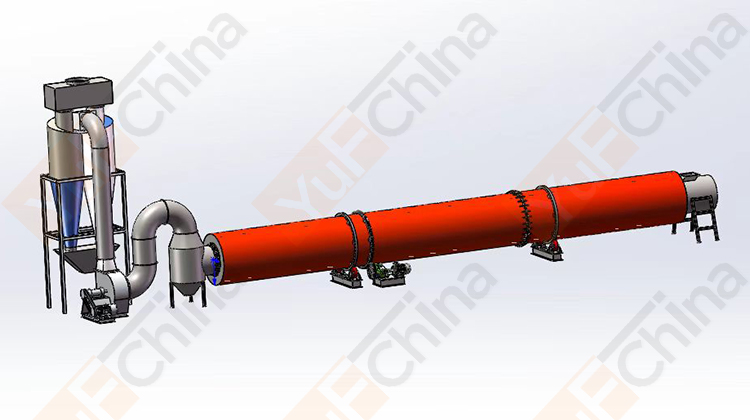

Introduction to ОҰ2Г—20m High-Humidity Dryer (New-Type Rotary Dryer)

With unique layered design and high efficient drying capabilities, the Multi layer Saw Dust Dryer plays an important role as an indispensable important drying equipment for many industries. Designed to reduce initial moisture from 70% to 10вҖ“15 % with higher production output, the Biomass Dryer with special structure inside the cylinder to take full usage of thermal efficiency.

Working Principle of Multi-Layer Dryer with New Technology

The Energy-efficient dryer adopts a vertical, multi-stage cylinder structure. Materials enter from the top and undergo a helical downward movement through multiple layers of baffles. Hot air (generated by steam coils or biomass combustion) is introduced from the bottom and flows upward in countercurrent, forming a countercurrent heat exchange system. Key principles include:

1.Layered Drying: Each layer of baffles extends the material residence time, ensuring uniform moisture removal.

2.Heat Recycling: Waste heat from the upper layers is recycled to the lower layers, improving overall thermal efficiency by 15вҖ“20% compared to single-layer dryers.

3.Dynamic Material Distribution: Rotating lifter plates continuously toss and spread materials, preventing agglomeration and enhancing contact with hot air.

Parameter of ОҰ2Г—20m Intelligent Humidity-Controlled Dryer

| Model | ОҰ2.0Г—20m |

|---|---|

| Cylinder Diameter | ОҰ2000mm |

| Cylinder Length | 20m |

| Rated Power | 18.5kW with 55kW fan motor |

| Heating Source | Hot Air / Biomass & Pellet Combustion |

| Inlet Moisture | вүӨ70% |

| Noise Level | вүӨ85dB |

| Weight | 35-40 tons |

GET IN TOUCH WITH US