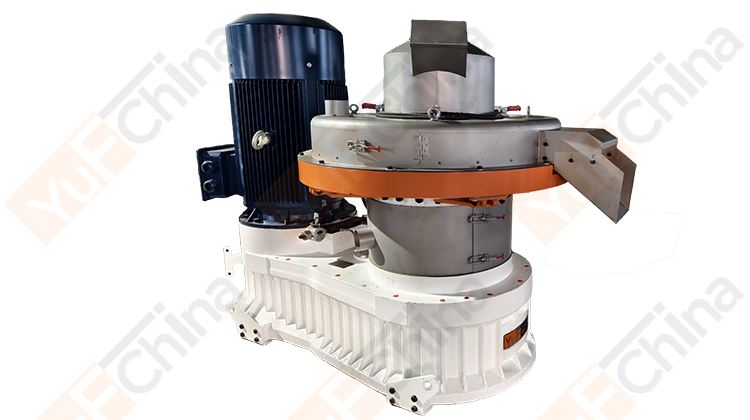

1600 Wood Chipper with 110kW – Heavy-Duty Industrial Model

Disc Wood Chipper Structure

The structure of the disc chipper is simple, making it easy to operate and maintain. The in-feed and discharge ports can be designed in different directions based on specific needs, enabling seamless integration with belt conveyors for efficient feeding and discharging through the chipper system.

Features of Large Wood Disc Chippers

1.Compact structure with a reasonable layout ensures easy installation and maintenance-friendly operation. The cutter disc features wear-resistant chromium plating, significantly prolonging its service life.

2.High-capacity processing with adjustable wood chip length within a specified range, adaptable to diverse industrial needs.

3.Versatile power options: Supports electric motors, diesel engines, or gasoline engines. The mobile design (equipped with movable wheels) enables unrestricted worksite flexibility.

Wood Disc Chipper Applications

1. Used in paper mills

2. Used in furniture factories

3. Used in power plants and boiler plants

4. Used for producing biomass pellets

Technical Parameter

| Model | 1600 |

|---|---|

| Rotation speed (rpm) | 620 |

| Blade QTY (piece) | 6 |

| Chip size (mm) | 20-35 |

| Input size (mm) | 420x420 |

| capacity (t/h) | 15-25 |

| Main power (kw) | 110 |

| Feed + discharge motor (kw) | 3+3 |

| Disc diameter (mm) | 1600 |

| Weight (t) | 6.58 |

| Feed conveyor length (mm) | 6000 |

| Discharge conveyor length (mm) | 10000 |

Disc Chipper Machine Models

| Model | Blade qty | Capacity (t/h) | Main power (kw) |

|---|---|---|---|

| 1150 | 6 | 10-12 | 55 |

| 1300 | 6 | 13-18 | 75 |

| 1600 | 6 | 15-25 | 110 |

| 1800 | 6 | 30-40 | 160 |

GET IN TOUCH WITH US