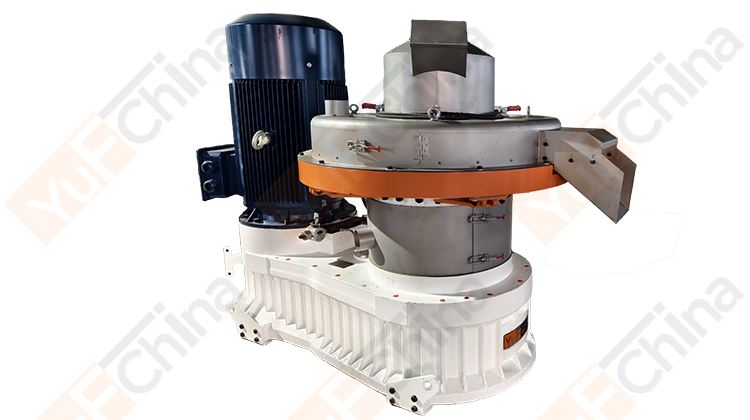

55KW 460 Ring Die Granulator

Raw Materials & Applications for Wood Pellet Press Machine

The wood pellet press machine (or pelletizer machine) processes a wide range of biomass materials to produce high-density pellets for fuel, industrial use, or animal bedding. Key raw materials include:

Wood residues: Logs, branches, sawdust, wood shavings, and wood offcuts.

Agricultural waste: Rice husk, rice straw, wheat straw, corn stover, sorghum stalks, soybean stalks, cotton stalks, sunflower straw, peanut stalks, grape pomace, and miscanthus.

Energy crops: Bamboo debris, sugarcane bagasse, and EFB (empty fruit bunches) from palm oil extraction.

Herbaceous biomass: Grasses, shrubs, and crop residue such as alfalfa and miscanthus.

These materials are densified into uniform pellets through ring die pellet mills or flat die pelletizers, enabling efficient biomass granulation. The resulting pellets serve as sustainable alternatives for heating, power generation, and industrial energy needs.

Vertical Ring Die Granulator - A High-Performance Pelletizing Solution

The XGJ series vertical ring die granulator stands out from conventional ring die pellet machines with its innovative vertical structure and precision assembly process. Engineered for efficient processing of diverse biomass resources, this heavy-duty pelletizer features optimized pressurization systems and high-capacity production capabilities. Key enhancements include reinforced main shaft transmission, wear-resistant ring dies, and automated lubrication mechanisms, ensuring stable operation and elevated particle formation rates. Its advanced material compaction design achieves uniform compression ratios while maintaining low energy consumption, making it an ideal choice for sustainable biomass pellet production with minimized dust emission.

Biomass Pellet Machine Expertise

We specialize in designing and manufacturing advanced biomass pellet mills and turnkey pellet production solutions, featuring high-efficiency palm fiber processing capabilities. Our vertical ring die pellet machines adopt innovative waste biomass recycling technology, utilizing gear drive transmission and automated lubrication systems for optimal performance. The complete pelletizing systems efficiently convert agro-forestry residues, palm oil empty fruit bunches (EFB) and other organic materials into premium biofuel pellets, supporting sustainable green energy initiatives.

55KW 460 Biomass Pellet Machine Technical Data

| 55KW XGJ460 | |

|---|---|

| Model | 55KW XGJ460 |

| Capacity | 600-800 KG/Hr |

| Motor Power (Kw) | 55KW +1.5+0.37+0.37+3 |

| Raw Material | Agro-forestry residues and waste. |

| Usage | wood processing plants, fuel plants, fertilizer plants, chemical plants |

7th Generation Wood Pellet Machine Technical Data

| Model | Power(kw) | Capacity(t/h) | Pellet Size(mm) | Dimension(mm) | Weight(t) |

|---|---|---|---|---|---|

| XGJ460 | 55 | 0.6-0.8 | 6-12 | 1700*1000*1580 | 3 |

| XGJ560 | 90/110/132 | 1.1-2.1 | 6-12 | 2240*1200*1650 | 4-5 |

| XGJ700 | 160 | 2-2.5 | 6-12 | 2680*1300*2100 | 8.5 |

GET IN TOUCH WITH US