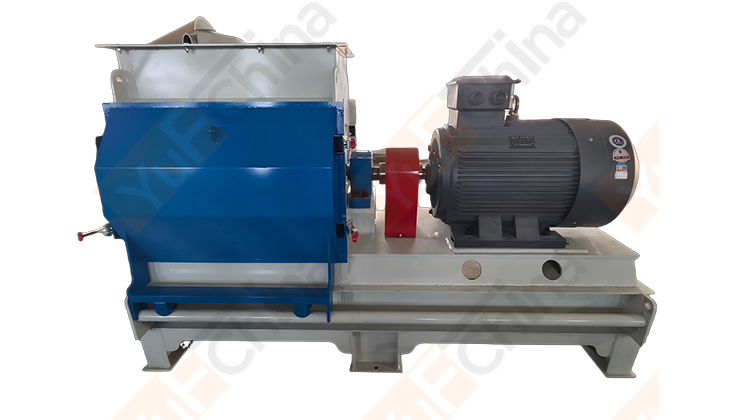

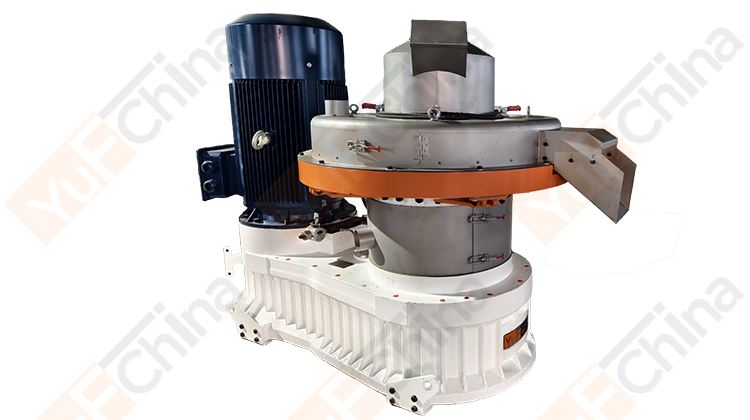

90KW 65Г—100 Sawdust Crusher Machine for Wood Processing

Sawdust Grinder Introduction

The hammer mill features direct drive transmission, optimized hammer placement, and adjustable hammer-to-screen clearance, ensuring uniform particle sizing and efficient crushing. Its secondary impact crushing chamber enhances material processing. Premium imported bearings with real-time temperature monitoring reduce operational heat, extending service life.

Optional screen sizes, a quick-access inspection door, and pneumatic/spring-loaded screen retention enable rapid screen swapping and low-maintenance operation.

High quality imported bearing, tungsten carbide alloy spray hammer.

Raw materials of Sawdust Maker

The raw material to make scraps can be from agriculture ,like rice husk, sunflower husk,forestry like wooden log,timber chip,sawdust,wood powder; Rubber, cement, ash and different chemical materials, such like low adhesion rate, difficult or gentle materials.

Advantage of Wood Chips To Sawdust Machine

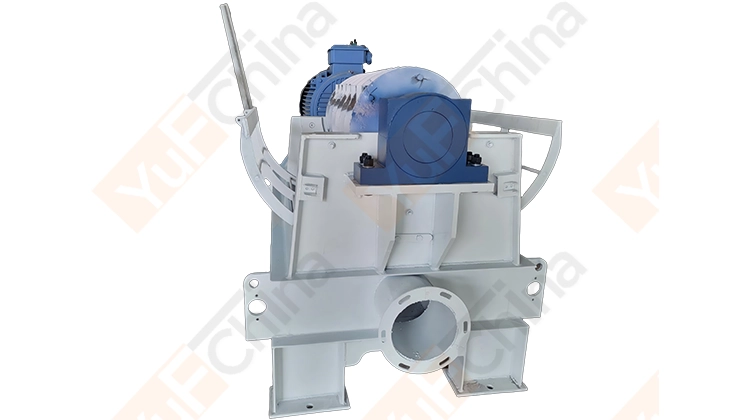

* Overall base design.

* It is for less land occupancy. High structural strength and beautiful appearance of the feed hammer mill.

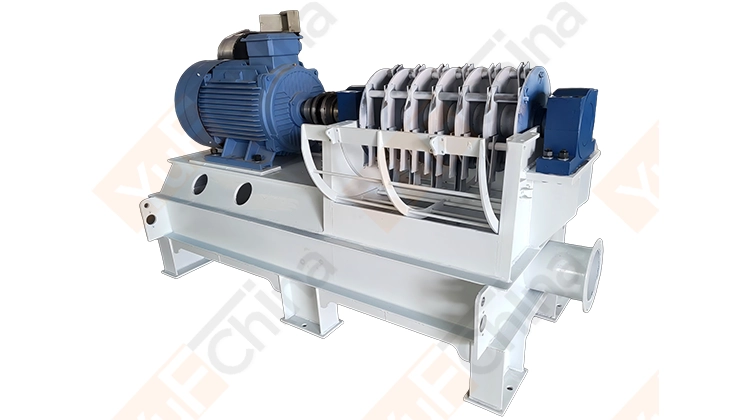

* Optimal placement of rotors, making the current fluctuations within 10%.

* Improvement on structure and the chosen material of hammer, increasing crushing efficiency 20%.

* Movable operating door and linkage sieve press structure, more convenient for operation and maintenance.

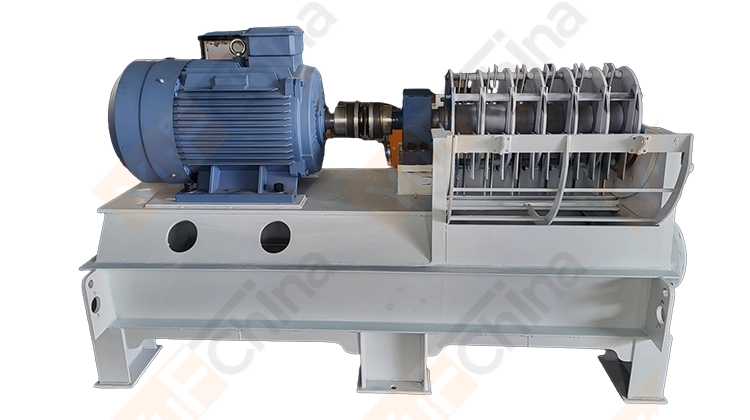

* The crusher is equipped with siemens motor and high quality Imported bearings, resulting in long service life and low maintenance cost;

* The grinding chamber is of tear circle shape, effectively eliminating the circular flow in the grinding process and getting higher capacity;

* The Bottom of grinding chamber is fitted with U-shape double grinding structure, further improving the capacity with evener particle size;

* Rotor passes accurate dynamic balancing test, resulting in low equipment noise and smooth running;

* Both coarse and fine grinding is realized through adjusting the gap between beater/hammers and screen;

* Hammers edge is vacuum-welded by special alloy steel, resulting in long service life of the feed crusher machine.

Technical Data

| 65X100 hammer mill | |

|---|---|

| Name | 65X100 hammer mill |

| Capacity | 2.5-3 t/h |

| Power(kw) | 90KW |

| Hammers qty | 96pieces |

| Weight | 2.9T |

| Dimension | 2.2x1.8x1.6m |

Complete set -Hammer mill, Fan 15kw /18.5 kw, ПҶ1000/ПҶ1200 cyclone, air locker, bag filter, wind pipes.

Hammer Mill Technical Data

| Model | Power(Kw) | Capacity(T) |

|---|---|---|

| 65x55 | 55 | 1-2 |

| 65x75 | 75 | 2-2.5 |

| 65x100 | 90 | 2.5-3 |

| 65x100 | 110 | 3-3.5 |

| 65x120 | 132 | 4-5 |

| 1300x1000 | 160/185 | 6-8 |

| 1600x1000 | 220 | 8-10 |

GET IN TOUCH WITH US