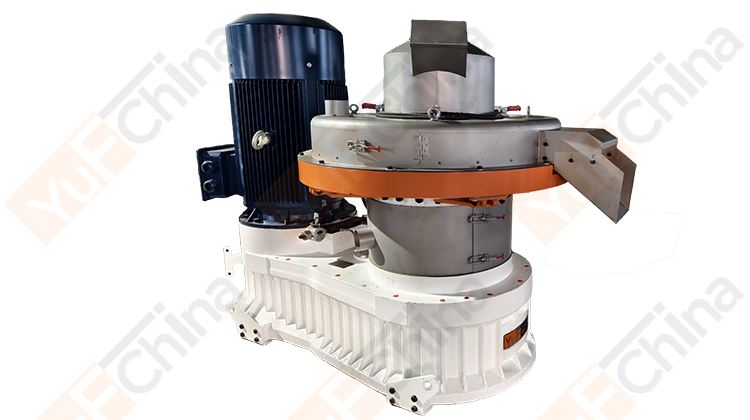

Wood Pellet Counterflow Cooler

Model: SKLZ

Main Power: 5.5 - 22 KW

Capacity: 1000KG - 12000KG/ Hour

Type: Counterflow cooling

Application: Wood Pellets, Animal Feed Pellets Cooling

Fucntion: cooling hot temperature pellet to room temperature

Introduction of machine for cooling pellets

The counterflow cooling principle is adopted to cool the pellets with high temperature and moisture. Hot air touches hot pellets and cool air touches cool pellets so as to avoid the pellet surface crack caused by sudden cooling produced by direct touching between cool air and hot pellets. At the same time, the airlock is used for feeding and space of air inlet bigger, therefore it can get better cooling effects;

The equipment is mainly used for the cooling of the high temperature pellets, from 80 В° C to 90 В° C and the moisture content of 17%-18% to a temperature slightly higher than the room temperature, moisture content 12% to 13%, making it easy to transport, storage and preservation.

Features

* Slide reciprocating discharger has smooth and reliable discharging, low residue;

* Low power consumption, ease of operation;

* Pellet temperature after cooling is less than +3В°C~5В°C ambient temperature;

* Capable of cooling pellets.

Description of counterflow pellet cooler

1. Suitable for various pellet cooling, such as granulators, extruded materials such as granular materials, especially for cooling pellet.

2. Using counterflow cooling principle for high temperature and humidity of the pellets were cooled gradually cooling the material from the bottom up, to avoid chilling, non-explosive particles lumbar fracture.

3. octagonal cross-section of the cooling box, remove the cooling dead, more conducive to cooling treatment pellet.

4. The use of close air filter feed, the feed inlet to prevent channeling wind phenomenon, better cooling effect.

5. equipped with adjustable cone bulk institutions, uniform fabric.

6. reciprocating linear motion slide valve discharge mechanism, the material flow, adjustable flow.

7. The front of the device to open the access door, side and roof start viewing window for easy observation equipment operation

Technical Data

| Model | Capacity (t/h) | Fan power (kw) | Cooling time | Cyclone diameter (cm) |

|---|---|---|---|---|

| LQ-1.2 | 0.8-1.5 | 5.5 | вүҘ10 mins | ОҰ80 |

| LQ-1.5 | 1.5-3 | 7.5 | ОҰ80 | |

| LQ-2.5 | 3-5 | 11 | ОҰ100 | |

| LQ-4 | 5-8 | 22 | ОҰ120 | |

| LQ-6 | 8-12 | 30 | ОҰ130 |

GET IN TOUCH WITH US