How to Quickly Start a Biomass Pellet Manufacturing Business: A Comprehensive Guide from Feedstock to Scale

Raw Material Analysis: The Starting Point of Biomass Pellet Production

1. Raw Material Type and Pretreatment Requirements

Common Raw Material Categories:

Agricultural Waste: Rice Husks, Corn Straw, Wheat Straw, Cotton Stalks, etc.

Forestry Waste: Wood Chips, Branches, Sawdust, Wood Scrap, etc.

Other Organic Waste: Peanut Shells, Coconut Shells, Bamboo Shavings, etc.

Raw Material State Analysis:

Crushed Raw Material (Sawdust-like): Can be directly processed into the pelletizing process, saving investment in pre-processing equipment.

Uncrushed Raw Material: Pretreatment equipment selection depends on the raw material characteristics.

Branches and Wood Scrap: Requires prior processing in a shredder.

Straw: Requires a hay chopper or pulverizer.

Large Wood: May require initial processing in a crusher.

Key Point: The physical form of the raw material directly influences the type and cost of pretreatment equipment required.

2. Raw Material Moisture Management

Humidity is a key factor affecting pelletizing quality and efficiency.

Moisture Classification and Treatment Options:

15%: Ideal, direct pelletizing possible

15-20%: Direct pelletizing can be considered, but may affect yield and quality consistency

20%: Drying is required

Drying Options:

Natural Air Drying:

Advantages: Zero energy cost

Disadvantages: Large footprint, weather-related, and low efficiency

Suitable for: Small-scale production, no rush to start production, and ample drying space

Dryer Treatment:

Drum Dryer: Suitable for continuous production

Advantages: High efficiency, unaffected by weather

Disadvantages: High equipment investment and operating costs

Professional Recommendation: For raw materials with a moisture content >25%, it is strongly recommended to install a drying system. Failure to do so will result in increased mold wear, low yield, and poor pellet formation.

Production Scale Selection and Equipment Configuration

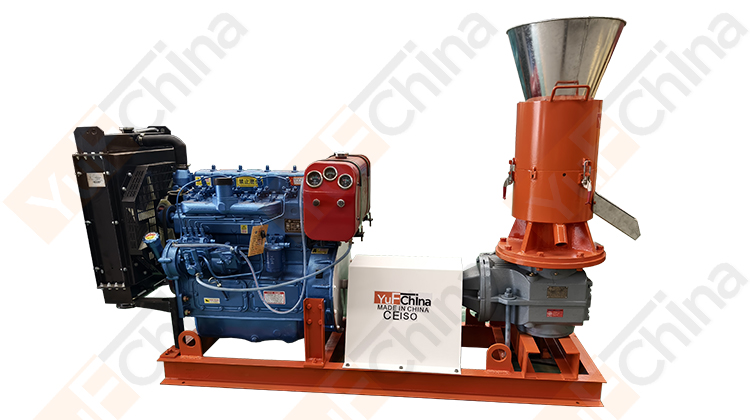

1. Small Production Line: 12 tons/hour

Suitable Clients:

Startups

Sole Proprietors

Farms or Forestry Owners

Regional Small-Scale Suppliers

Typical Configuration:

Raw Material Handling ‚Üí Crusher (if required) ‚Üí Small Dryer (if required) ‚Üí Small Pellet Mill ‚Üí Cooler ‚Üí Packaging

Advantages:

Low Investment

Minimum Site Requirements

Low Power Requirements

Challenges:

High Unit Production Cost

High Dependency on Labor

2. Medium Production Line: 28 tons/hour

Suitable Clients:

Professional Biomass Pellet Producers

Medium-Sized Farm Cooperatives

Regional Distributors

Typical Configuration:

Raw Material Pretreatment Line ‚Üí Medium-Sized Drying System ‚Üí Pellet Mill ‚Üí Cooling and Screening System ‚Üí Packaging/Bulk Packaging

Key Considerations:

1. Multiple pellet mills in parallel are recommended for increased flexibility.

2. A primary dust removal system is required.

3. Consider the raw material storage system design.

Advantages:

Significant economies of scale

Can meet the needs of commercial customers

Higher automation levels are possible

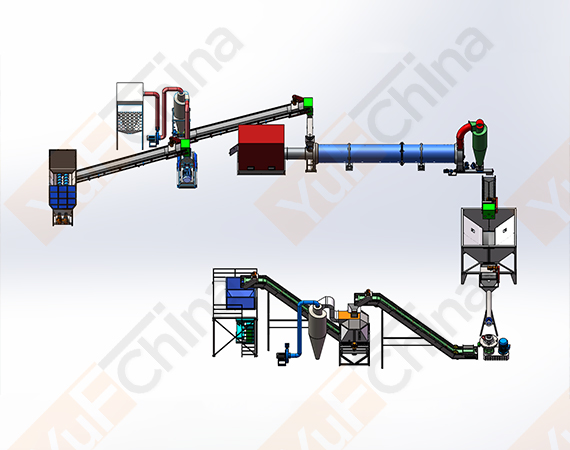

3. Large-scale production lines: 10 tons/hour or more

Suitable customers:

Industrial manufacturers

Export-oriented enterprises

Integrated with power plants or large-scale heating systems

Typical configuration:

Raw material receiving system ‚Üí Automated pretreatment line ‚Üí High-efficiency drying system ‚Üí Multi-unit pelletizing plant ‚Üí Automated packaging and palletizing

Key features:

Highly automated control system

Comprehensive dust removal and environmental protection facilities

Raw material and finished product storage systems

May include a steam conditioning system

Professional advice:

A detailed feasibility study is required

Consider the possibility of cogeneration

A professional operations team is required

Decision-making Flowchart from Raw Materials to Production

Getting Started

‚Üď

Analyze Raw Material Characteristics

‚Ēú‚ĒÄ Physical Form ‚Üí Is Crushing/Shredding Required?

‚ĒĒ‚ĒÄ Moisture Level ‚Üí Is Drying Required?

‚Üď

Determine target market capacity

‚Üď

Choose production scale

‚Ēú‚ĒÄ 12t/h ‚Üí Small configuration

‚Ēú‚ĒÄ 28t/h ‚Üí Medium configuration

‚ĒĒ‚ĒÄ 10t/h+ ‚Üí Large configuration

‚Üď

Equipment selection and supplier selection

‚Üď

Plant and infrastructure preparation

‚Üď

Installation and commissioning

‚Üď

Trial production and optimization

‚Üď

Formal operation

Key factors for success and practical suggestions

1. Raw material supply chain development

Ensure a stable and reliable source of raw materials

Consider the impact of seasonal raw material fluctuations

Establish raw material quality inspection standards

2. Golden rules for equipment selection

Mold material selection: Ring molds are recommended to use high-quality alloy steel or stainless steel

Main motor brand selection: Well-known brands are recommended for stability

Control system: PLC control is recommended for medium-sized and larger production lines

3. Energy efficiency optimization

Recover waste heat (especially in the drying process)

Apply motor variable frequency technology

Optimize production scheduling to reduce start-up and shutdown losses

4. Market strategy

Initially focus on the local market to reduce logistics costs

Consider differentiated product strategies (such as high-calorific value pellets).

Understand and pursue potential government subsidy policies.

5. Avoiding Common Pitfalls

Avoid overinvestment and idle capacity

Be wary of the trap of low-priced, low-quality equipment

Emphasis on dust and explosion safety measures

Conclusion

Starting a biomass pellet manufacturing business requires comprehensive consideration of raw material characteristics, production scale, and market demand. Starting small to validate the business model and then gradually expanding production capacity is a more reliable strategy. It is recommended to collaborate with experienced equipment suppliers and technical consultants to conduct a detailed feasibility analysis before making an investment decision. With growing global demand for renewable energy, the biomass pellet industry holds broad prospects, but the key to success lies in refined operational management and continuous technological optimization.

GET IN TOUCH WITH US