New Type Multi-layer Dryer

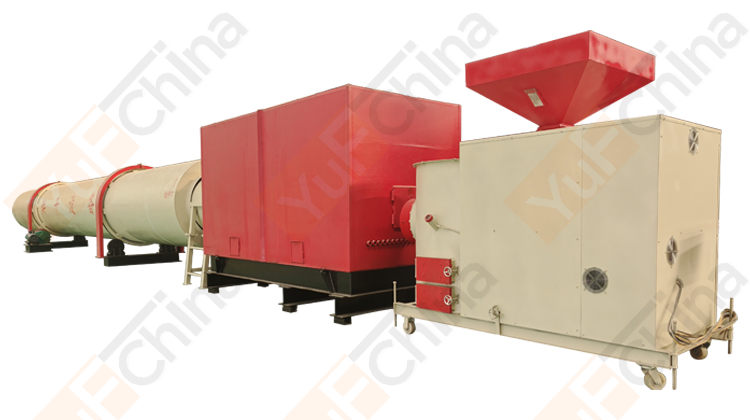

Introduction of High humidity Multi Layer Dryer ( New Type rotary drye )

With unique layered design and high efficient drying capabilities, the Multi layer Saw Dust Dryer plays an important role as an indispensable important drying equipment for many industries. Designed to reduce initial moisture from 70% to 10 / 15 % with higher production output, the Biomass Dryer with special Structure inside the cylinder to take full usage of thermal efficiency.

Higher Production Capacity for the latest Biomass Pellet Sawdust Drier

Big Capacity Continuous Dryer with Diameter 1800mm with hourly capacity 4-6 tons per hour Multi-layers Dryer YuFChina with Diameter 2 meters with output 6-8 tons per hour. It is doing greater compare with the market drum dryers with similar specifications and prices.

Advantages of Layer Dryer with New Technology

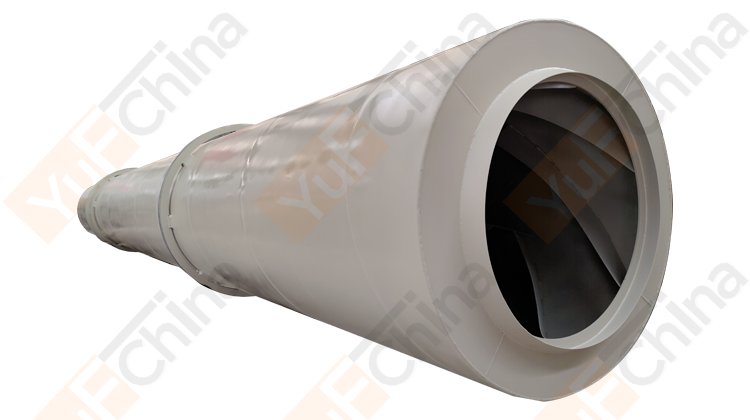

1.Special lifting plates reinstalled to fulfill as much thermal efficiency as possible.

2.Multi layers installed inside dryer cylinder for spread the hot air to keep the heat is in full contact with the materials, so to improve the thermal energy transfer and accelerate the drying process.

3.Multi pipes with separated lifting plates in each tubes, enlarged heating ares, to guarantee the significant drying effect.

4.Positive pressure discharge method, high pressure fan with big power, which extending the service period of the fan, keep uniform temperature inside the Sawdust Dryer, and avoid any discharge clogging.

5.Inverter Design with adjustable speed for the drying cylinder, feeding device, as well as fan rotating. Flexible types, sizes of raw materials with different humidity.

6.Less Land Occupied, High Capacity, Reasonable Input.

With optimization design, the Sawdust Layer Dryer not only improves thermal efficiency, production capacity and service period, but also adapts to the different requirements of materials and environment. It is the most reliable and efficient solutions for your biomass drying system.

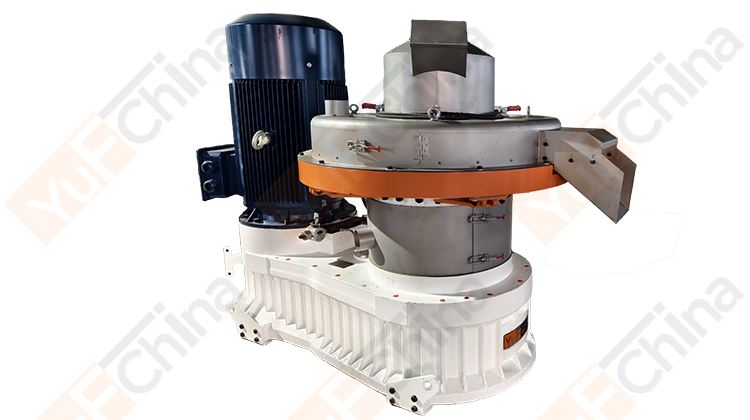

Why need a Sawdust Drying Machine for Bio Pellet Production Line?

To guarantee the qualified output biomass pellet and briquettes with high density and smooth outlook, we should restrict control the moisture and sizes of sawdust before the pelletizing press. YuFChina Efficient Sawdust Dryer can reduce the humidity of sawdust or wood chips faster and more efficient.

Wet Sawdust Dryer Applications

1.Biomass materials such as sawdust, wood chips, crop stalks, grass, leaves, sugarcane bagasse, banana leaf, etc.

2.Chemical products like fertilizer, metal powder, sugar, building materials, industrial salts, distillerвҖҷs gains, medical, etc.

3.Animal feed and agricultural waste such as starch residue, shells for crayfish & shrimp, fish meal, etc.

4.Mining products like coal, ore, sand, slag, clay, kaolin, etc.

Parameter of Moisture Sawdust Drier

| Name | Model | Power (kw) | Fan Power (kw) | Length (m) |

|---|---|---|---|---|

| Multi Layer Dryer | ОҰ1.8 | 11 | 45 | 16-20 |

| Multi Layer Dryer | ОҰ2 | 18.5 | 55 | 18-22 |

| Multi Layer Dryer | ОҰ2.2 | 22 | 55 | 20-24 |

| Multi Layer Dryer | ОҰ2.4 | 37 | 75 | 22-28 |

GET IN TOUCH WITH US