Precautions for Lubricating the Ring Die and Reducer Oil in Biomass Pellet Machines

Lubricant Addition Standards

1. Oil Selection: (This refers to the oil specifications. Select the appropriate model according to the equipment manual and actual production environment.)

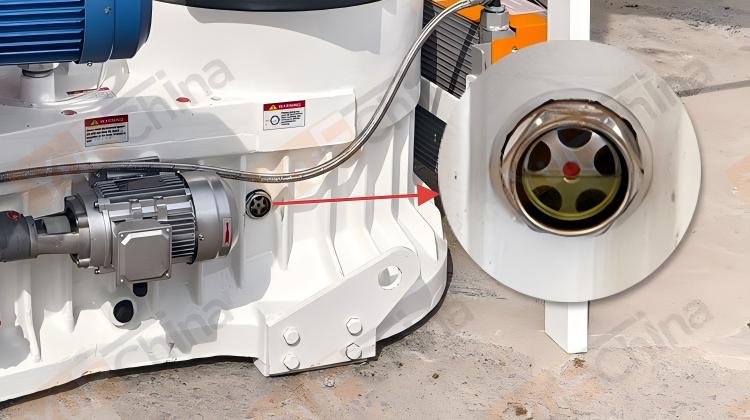

2. Oil Level Control:

В· The oil level should be maintained at 1/2 of the oil window.

В· Excessive oiling will increase operating resistance.

В· Insufficient oiling will result in poor lubrication.

Proper Oil Addition Methods

Addition Procedure:

В· Check the oil level after shutting down.

В· Use a dedicated oiling tool to add oil.

Replacement Cycle:

В· New Machine Commissioning: After 2472 hours of operation, inspect the reducer filter element to check for impurities such as iron filings and replace it promptly to prevent wear.

В· During Normal Operation: Replace the filter element approximately every 3,000 hours (approximately every six months to one year, depending on machine performance).

В· Shorten the replacement cycle in hightemperature environments.

Precautions

1. Strictly avoid mixing different brands of lubricants.

2. Regularly check for changes in oil quality.

3. Immediately replace the oil if any abnormality is detected.

4. Keep the oil filler port clean to prevent contamination.

Proper lubricant use can extend equipment life by over 30%. Users are advised to strictly adhere to standards to ensure stable and efficient production.

GET IN TOUCH WITH US