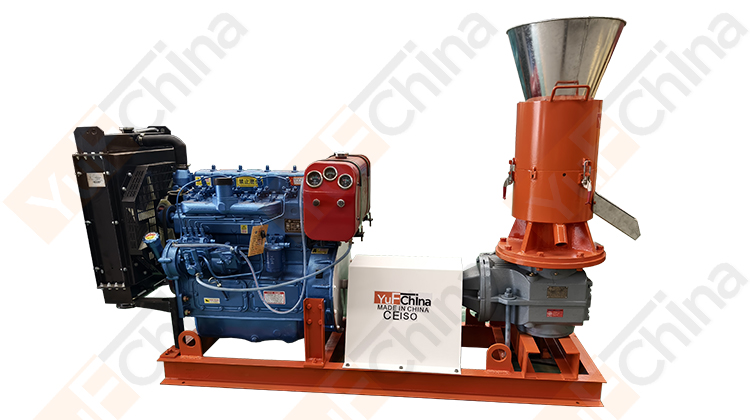

In-Depth Analysis of Biomass Pellet Machine Core Components: Ring Die, Press Roller, Main Shaft, and Gearbox

The design, material, and operating conditions of these components directly impact pellet formation efficiency, energy consumption, and equipment stability.

Ring Die: The "Heart" of Pellet Forming

Function

В· Extrudes the raw material into pellets through the die hole (usually 6-8mm diameter), determining pellet density and yield.

В· The material and heat treatment process directly impact wear resistance.

Common Problems

вқҢ Die hole enlargement (>10% of the designed hole diameter results in loose pellets and increased fines).

вқҢ Surface cracking (due to uneven heat treatment or hard impurities in the raw material).

Maintenance Tips

вң… Regular Inspection: Before each shift, inspect the die hole for deformation, damage, etc.

вң… Scientific Run-in: New ring dies should be run at low speed for two hours using a feedstock containing 30% sand to polish the die hole.

Press Roller: Key to Pressure Transmission

Function

В· Works with the ring die to extrude the raw material and form it.

В· The thickness of the press roller skin (wear-resistant layer) determines the replacement cycle (wear > 3mm requires replacement).

Common Problems

вқҢ Bearing lock (insufficient lubrication or overtightening).

вқҢ Press roller skin peeling (raw material contains metal impurities or heat treatment defects).

Maintenance Points

вң… Lubrication Standard: Upon startup, turn on the automatic lubrication pump and add high-temperature grease (temperature resistance > 150В°C). Check the oil line for unobstructed flow.

вң… Clearance Adjustment: Maintain a clearance of 0.1-0.3mm between the press roller and the ring die (calibrated with a feeler gauge).

Spindle: The Hub of Power Transmission

Function

В· Bears the rotating torque of the ring die.

Common Problems

вқҢ Journal wear (seal failure allows dust to enter the bearing seat).

вқҢ Fatigue fracture (long-term overload operation). Maintenance Key Points

вң… Vibration Monitoring: Install a vibration sensor. Shut down the machine for inspection if the amplitude exceeds 0.5mm.

вң… Seal Upgrade: Use labyrinth and lip seals for dual protection.

Gearbox: The Core of Power Conversion

Function

В· Reduces the motor's high speed to the ring die's operating speed.

Common Problems

вқҢ Gear tooth breakage (instantaneous overload or poor lubrication).

вқҢ Oil temperature too high.

Maintenance Key Points

вң… Oil Selection: Heavy-duty gear oil, replaced every 1000 hours.

вң… Temperature Control: Install an oil cooler (essential for high-temperature environments).

Optimization Suggestions

1. Preventive Maintenance: Establish a component replacement file and perform mandatory maintenance based on operating hours.

2. Accessory Upgrade: Prefer tungsten carbide ring dies and SKF bearings for better overall efficiency.

3. Intelligent Monitoring: Install temperature and vibration sensors for fault warnings.

Conclusion

Efficient operation of a biomass pellet machine depends on high-quality components and effective maintenance! Users need to have a deep understanding of the characteristics of core components in order to achieve cost reduction and efficiency improvement.

GET IN TOUCH WITH US